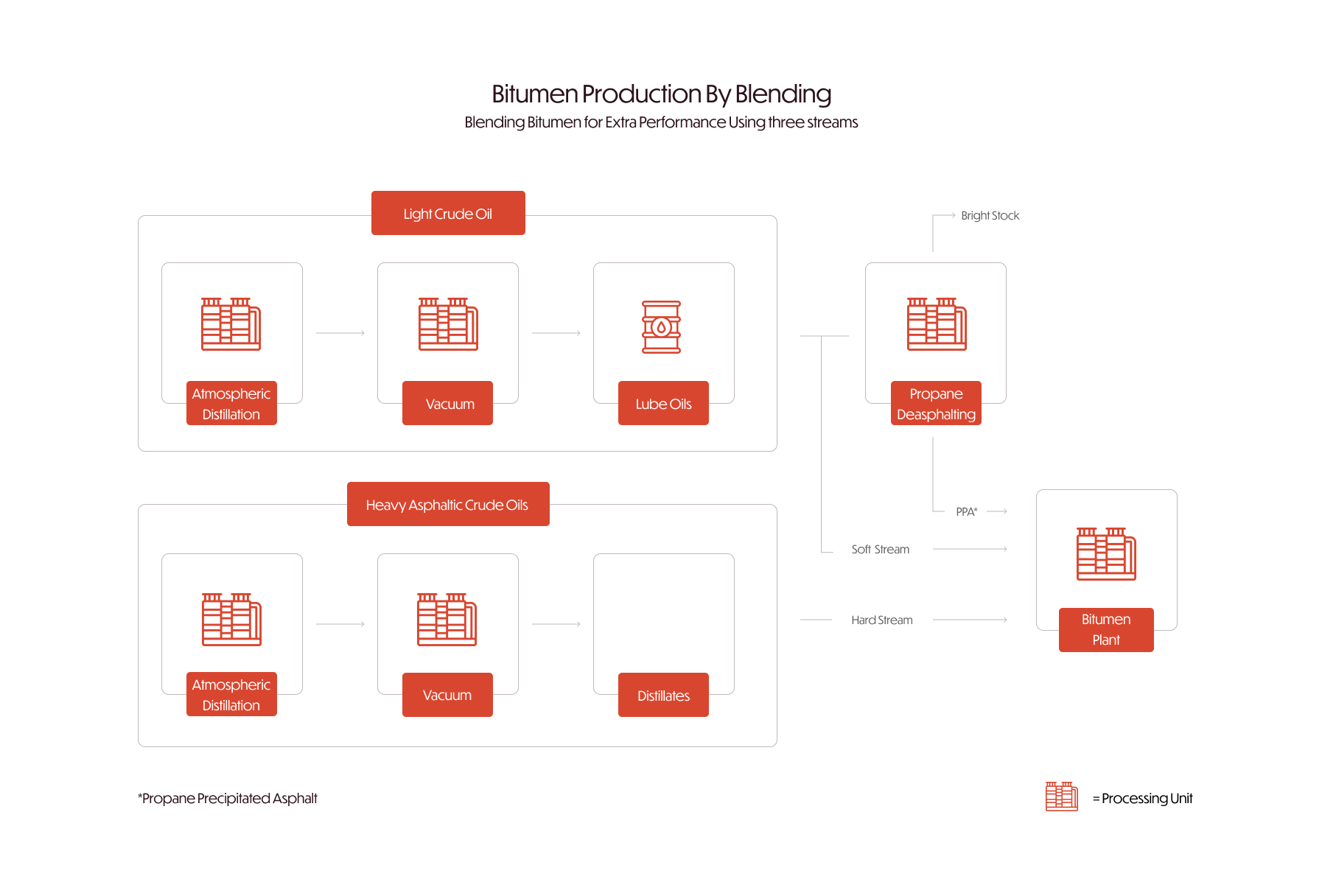

Performance of bitumen is related to its chemical composition which is determined by the crude source and the processing scheme used.

Major refiners have developed processes by which the chemical composition and rheology of bitumen may be controlled.

Our advanced bitumen emulsions provide a safer, more environmentally conscious alternative to traditional cutbacks, which many countries have banned due to environmental and health risks.

Our EP Emulsions range offers superior storage stability, ensuring performance even after long-distance transport and prolonged storage.

Designed for priming, bonding, surface dressing, cold recycling, and microsurfacing, these emulsions replace petroleum solvents while enhancing road durability, productivity, and environmental compliance.

Plus, all EP Emulsions are backed by an up-to-date Environmental Product Declaration (EPD) to give you the peace of mind that you’re choosing more responsible infrastructure solutions.

Not all bitumen ages the same.

Differences in crude sources and refining methods impact long-term performance, with Delta Tc values revealing a binder’s ability to resist cracking over time.

More oxidative refining results in lower Delta Tc values, increasing embrittlement risk.

Standards vary globally, but research shows values below -3°C signal potential cracking, with -5°C indicating high risk.

By understanding and managing these ageing effects, EP International ensures superior bitumen quality which results in longer-lasting and more resilient infrastructure.